Mass production has been automated for many years but now a big change is happening. The machines that are used for mass production today are fast but very hard to change. It can get very expensive and time consuming to even slightly change a product that is being mass produced.

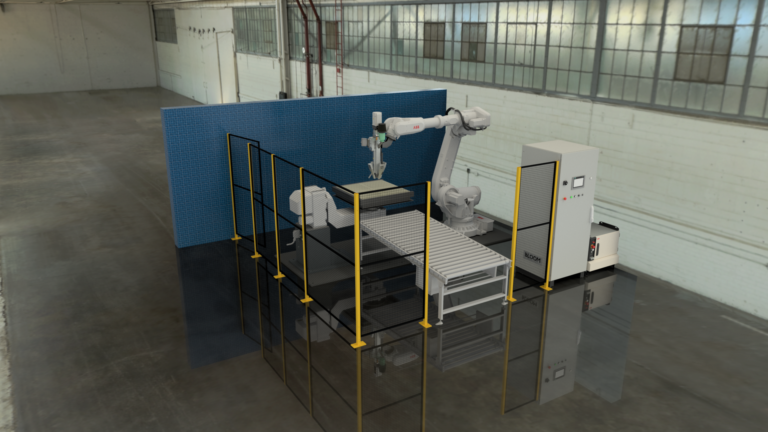

This can be avoided by using additive manufacturing machines for mass production. We here at BLOOM robotics have developed a turnkey additive manufacturing cell that can continuously produce mass customized prints. It works with a robotic arm and a positioner on which the printbed is placed. The robotic arm has a reach of 3200 x 3200 x 3665mm. We use the IRB6700 from our partner ABB robotics Benelux.

Because we use a positioner together with our robotic arm, we can get rid of unnecessary support material. This is possible since the positioner can continuously move the print, so we can use gravity instead of support material. This saves material, costs and time. The use of the positioner also provides the machine with extra axes for more complex shapes

In addition to 3dprinting, this machine can also be used for milling and plastic welding.

This machine is the pinnacle of industry 4.0!