Products

AR systems

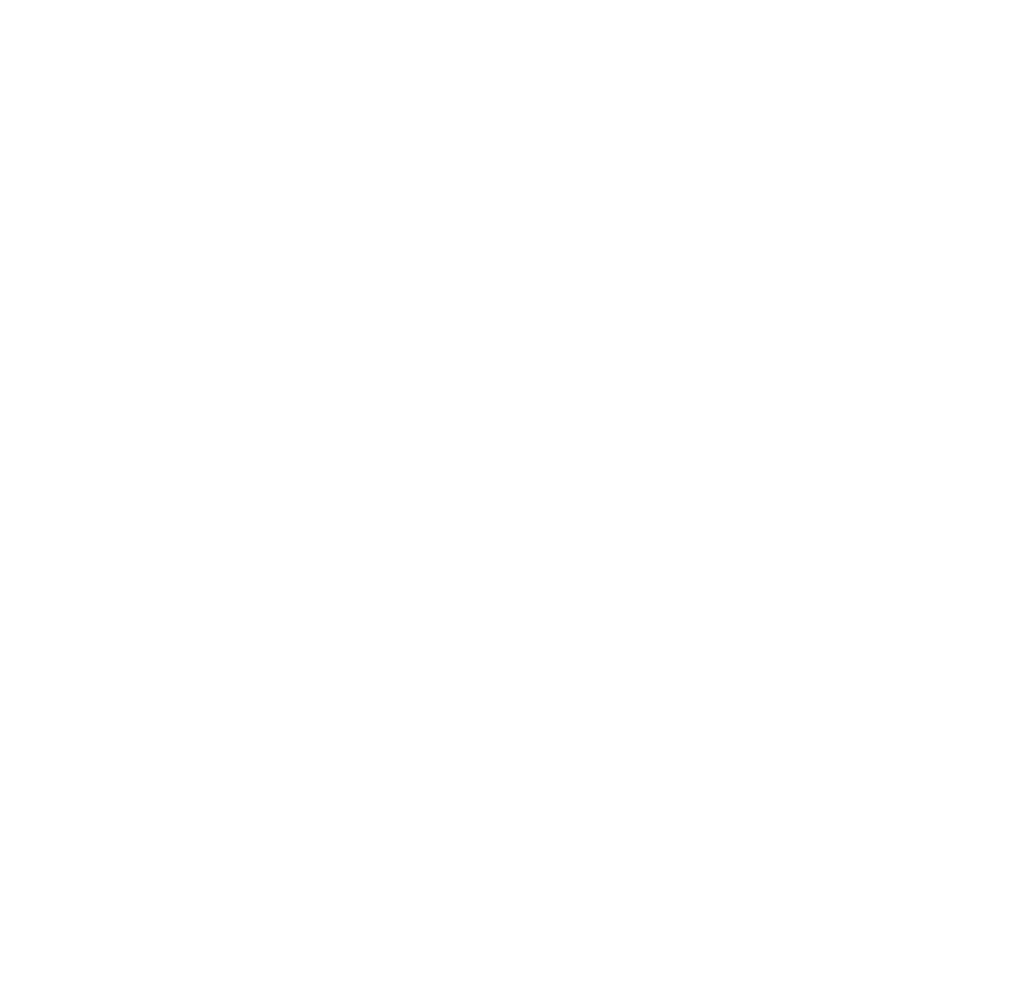

AR System Cell

The AR system cell is a turnkey additive manufacturing cell that can continuously produce mass customized prints. It works with a robotic arm and a positioner on which the printbed is placed. Because we use a positioner together with our robotic arm, we can get rid of unnecessary support material. This saves material, costs, and time. The use of the positioner also provides the machine with extra axes for more complex shapes.

In addition to 3dprinting, this machine can also be used for milling, plastic welding, and gluing.

AR System Mobile

The AR system mobile is a full production line for printing with pellets or flakes within a 20ft shipping container (size 6,06×2,44×2,59m). On this platform, the Royal Netherlands Army land operations print with PET bottles that are shredded into flakes. To achieve this, we have developed a robotic “direct flake” printer that can process the crushed bottles directly. This eliminates energy, space, and time-consuming production step, namely the compounding of PET chips into granules or filament.

But this platform can also be used for other purposes like concrete printing, steel printing, welding, milling, and, gluing.

AR System Gantry

This system is the biggest robotic large-scale 3d printing system on the global market.

The AR system gantry is a combination of a gantry and a robotic arm. This combination gives it the size possibilities that a gantry system offers but now with the level of precision and complexity that the 6-axis robotic arm offers. The serial production envelope is at least 12×4×6m. Together with the ADE30XL it can print at a rate of 20+ kg/h.

Components

ADE25

The ADE25 is our 25mm extruder. This extruder has been designed to work with a wide range of plastics and composites (PET-G / PET / PP / HDPE / PP-GF pallets). The extruder head weighs ± 30 kg and has a total length of 1100mm. It has an average output of 4.5kg/h with a maximum output of 8kg/h.

It has been made to be used on a robotic arm, but we can modify it for use on other types of additive manufacturing machines.

With our extruders we include all the electronics necessary, an electronics cabinet and a hopper system for the printing material.

ADE30f

The ADE30f is an extruder that has been designed to be able to print flakes instead of the normal pellets/granules. This means that it can directly print with shredded plastics which gives it a whole new range of possibilities.

The extruder has a maximum output of 8 kg/h and an average output of 4.5 kg/h.

With our extruders we include all the electronics necessary, an electronics cabinet and a hopper system for the printing material.

ADE30XL

The ADE30XL is our biggest extruder yet. It is flange mounted and can print with pellets and granules. It can be used with a variety of different materials. The extruder’s maximum output is 25 kg/h, with an average output of 20 kg/h.

With our extruders we include all the electronics necessary, an electronics cabinet and a hopper system for the printing material.

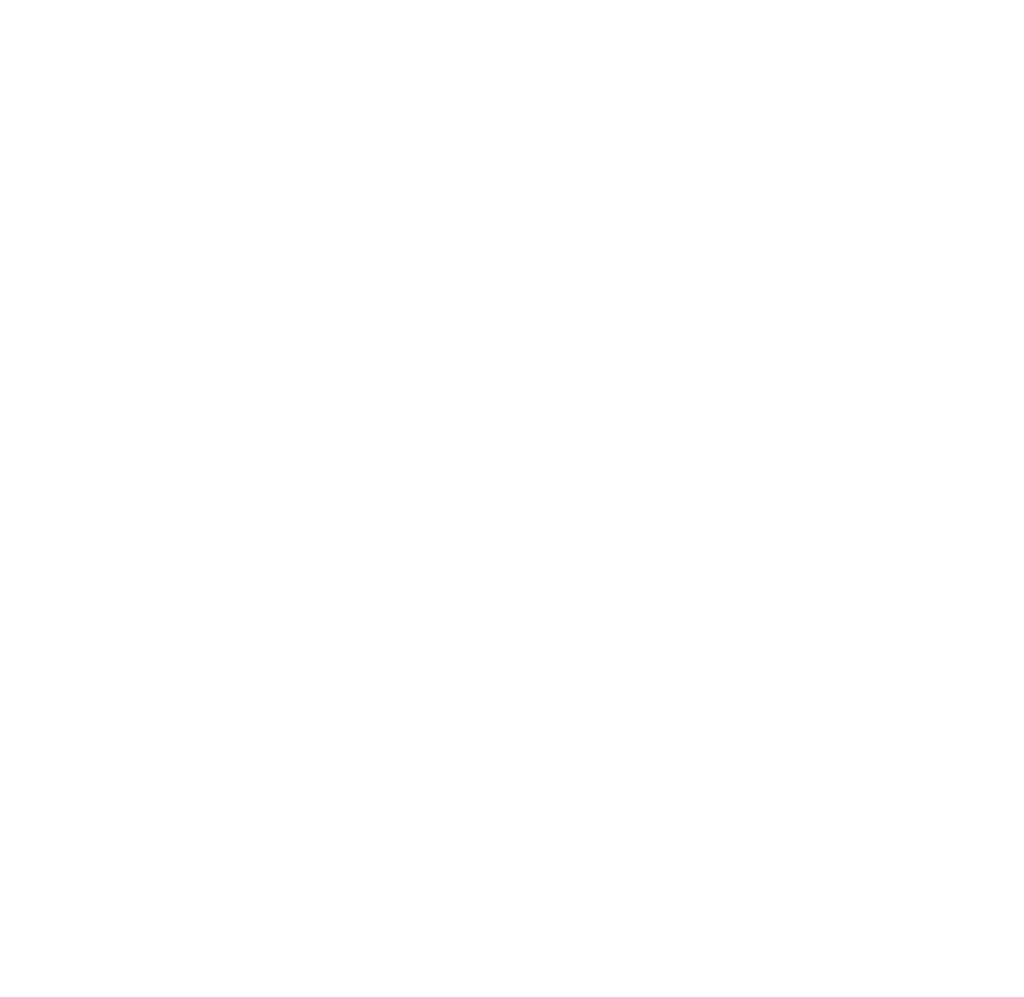

AR - Printbed

Solutions

We provide a variety of printbeds for our various additive manufacturing machines. Our main options are the PBh and PBm.

The PBh is a horizontal stationary printbed that is mounted on the floor next to one of our machines. The PBm is a printbed mounted on a positioner that allows it to move in tandem with the robotic arm, allowing us to eliminate unnecessary support material. For our gantry-based machine we make a custom printbed that best suits your needs.

Thermal telemetry

During the 3d-printing process a lot can happen and most additive manufacturing machines don’t see what they’re doing and keep printing as programmed. With our thermal telemetry system the robot can make changes according to what is needed and make sure you get the highest possible printing quality.

The thermal telemetry system works by using a thermal camera mounted on the extruder. This camera gathers and saves information that it uses to improve on the printing quality and to further adjust the printing efficiency for future prints.

Software

Software

We have developed real3D software that allows us to 3dprint without the need for unnecessary support material.

We can develop custom software to make your production process more efficient. From process automation, process control up to production planning, production data collections for industry 4.0 purposes.

For example we can connect your CRM orders to automatically generate the required models and create an easier to use flow to get to the printing process faster.

Services

Services

We here at BLOOM Robotics have a lot of in-house expertise and we are willing to share this in the form of advisory consults. We offer advice on how you could utilize additive manufacturing in your own production process.

Our help can get you set on the right path to a fully automated future.

.

Interested in our products or services?

For more information on our products or services please contact us. We are happy to help and provide you with a demo.